Motion Control & Automation

Modernizing drives, controls, and automation with minimized downtime — tailored for printing, packaging, and converting lines.

Overview

Machinery Solutions Group modernizes legacy drives and controls on a defined scope of work. We focus on supported platforms, practical retrofits, clear documentation, and cutovers that minimize downtime for printing, packaging, and converting lines.

Quick Facts

- Supported platforms: Siemens, SINAMICS & others

- Program types: single-machine → multi-line

- Focus: minimize downtime, clear documentation

Core Services

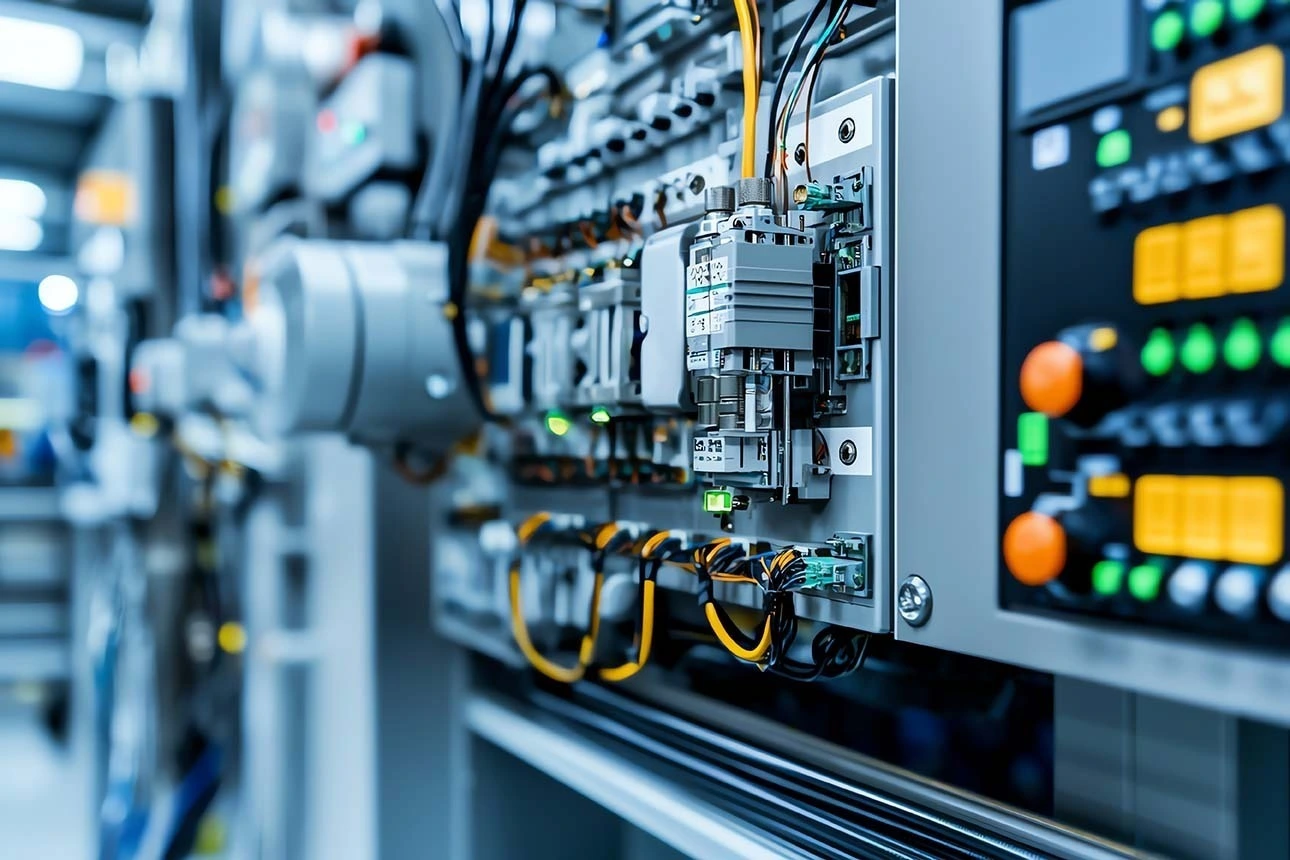

Drive & PLC Modernization

Siemens S7-1500 / SINAMICS; other platforms on request.

AC Drive Upgrades

SINAMICS G120/S120 replacements, motor setup, cabinet retrofit.

DC→AC Conversions

Torque/speed matching, feedback strategy, case-by-case.

HMI/SCADA Updates

Screen refresh, alarm cleanup, recipes, user roles.

Motion Control Improvements

Register, tension, servo conversions, web handling systems.

Remote Diagnostics

Secure access per IT policies, enablement only.

AC & Drive Upgrades / Replacements

Section drive work for infeed, chill, folders, unwind/rewind with VFD modernization and commissioning reports.

Section Work

Infeed, chill, folders, unwind/rewind- Section drive removal & replacement

- Cabinet fit & wiring verification

- Start-up & tuning

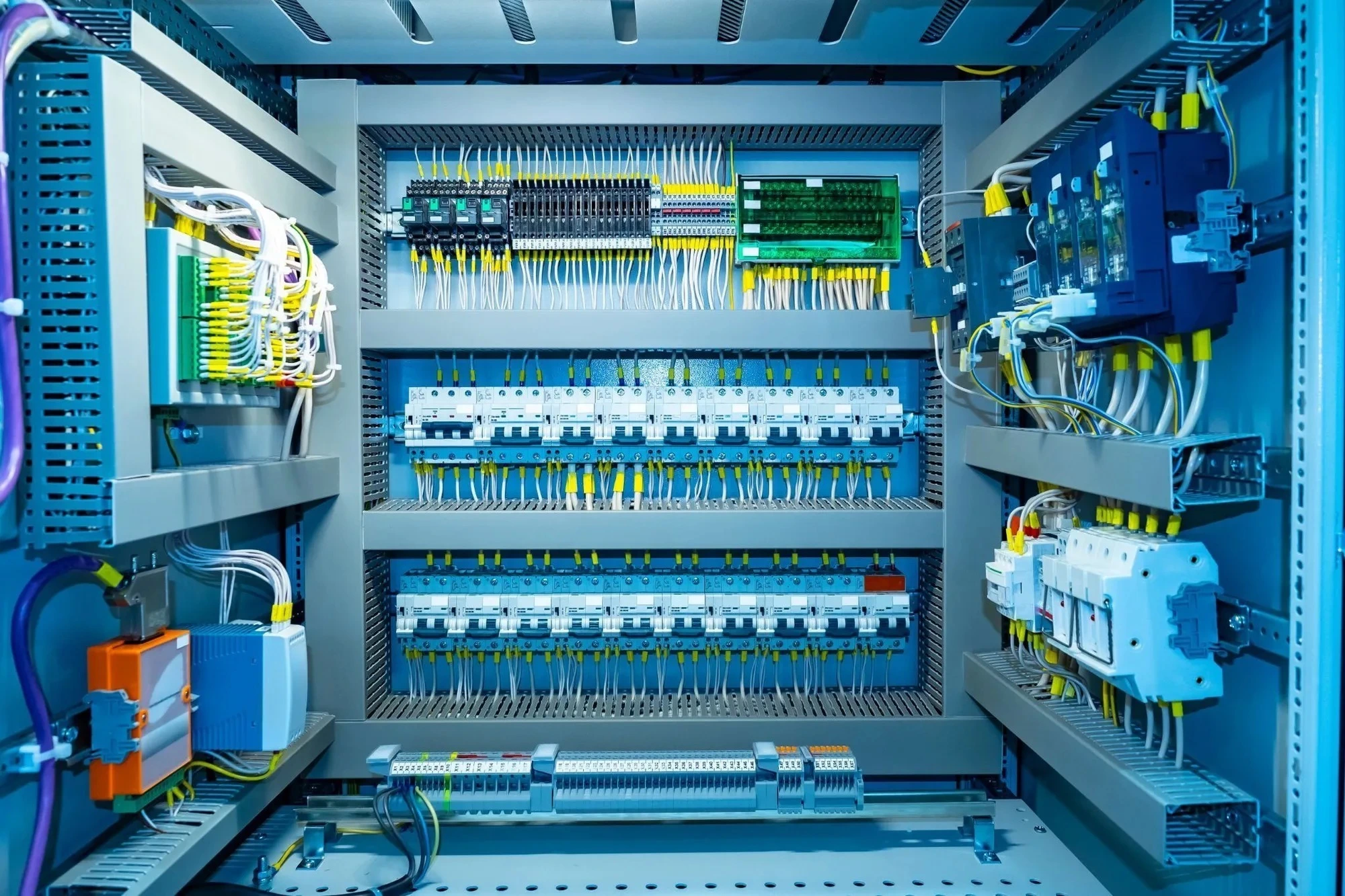

VFD Modernization

Reactors, filtering, cable spec, groundingDrive backups, start-up report, as-built updates, and spares recommendations.

Example Retrofit Packages

- G120/S120 conversion

- Filter / reactor

- Motor matching

- Parameter backups

- Tension & feedback

- Testing plan

- WinCC Unified/TIA

- User roles & recipes

Where We Fit

Web offset, sheetfed, digital inkjet, bindery/finishing, inserters/mailroom. Packaging/converting lines and plant support systems. Single-machine upgrades through multi-line programs.

Applications

- Printing press lines

- Converting & rewinding

- Packaging automation

Process

Discovery & valuation → Site visit & review → Design & scope (SOW) → Build & test (FAT) → Installation & commissioning → Documentation & hand-off

What You Receive

- As-built electrical drawings

- Updated I/O lists

- PLC/HMI project files

- Drive backups & commissioning report

- Operator notes

- Acceptance checklist

Support Options

Warranty

Commissioning warranty windowWarranty details depend on SOW and equipment type.

Remote Support

Blocks or service agreementsSecure remote sessions per IT policy; periodic health checks.

Typical Outcomes

- Better diagnostics and recoverability

- Reduced obsolescence risk

- Smoother changeovers and stable tension

- Clearer total cost of ownership

Assumptions & Limits

Project Assumptions

What we assume for quoting & delivery- Performance gains depend on mechanical condition

- Remote access requires IT/security approval

- Safety compliance per scope; 3rd-party by others

- Rigging, freight, and site trades by others

Quote Checklist

- Machine/line: make, model, year + cabinet photos

- Current controls: drives/PLC/HMI, I/O counts

- Mechanical context: motors/HP, gearboxes, web width

- Goals: uptime, diagnostics, data/traceability

- Constraints: power, footprint, IT/security, timeline